Welcome to the exciting world of automated inventory management systems! If you’ve been grappling with chaotic stockrooms, lost items, and endless spreadsheets, then you’re in the right place. Automation is your ticket to organized, efficient, and error-free inventory management.

An automated inventory system is not just a fancy tool; it’s a game-changer for your supply chain management. It offers real-time tracking of your inventory, reduces the risk of human error, and allows you to make data-driven decisions. So, buckle up as we guide you through the process of implementing this system in your business.

What is an Automated Inventory Management System?

An Automated Inventory Management System, as the name implies, is a technology-based tool that automates the process of tracking goods and materials as they move through the supply chain. This system can handle a wide array of tasks, including tracking inventory levels, orders, sales, and deliveries. It replaces traditional methods of inventory management, such as manual record-keeping and spreadsheets, eliminating the tediousness and potential for human error.

This system is a lifesaver for businesses, as it provides precise and real-time information about their inventory. It assists in maintaining optimal stock levels, preventing both overstock and stockouts. Furthermore, it aids in accurate forecast planning, identifies fast-moving items, and reduces the time and resources spent on inventory management.

Major Benefits of Inventory Management Systems for Your Business

An automated inventory management system offers numerous benefits to businesses of all sizes. Some of the key advantages include:

- Real-time tracking: With a real-time view of your inventory, you can quickly identify stock levels, track shipments, and monitor customer orders. This helps you stay ahead of potential issues and make timely decisions.

- Reduced human error: Manual data entry can lead to human errors, which can be costly for businesses. A smart inventory management system eliminates the risk of these errors by automating data entry and tracking.

- Improved efficiency: By streamlining your inventory management processes, an automated system frees up more time and resources for other essential business tasks. This ultimately leads to improved overall efficiency and productivity.

- Cost savings: With more accurate forecasting, optimized stock levels, and reduced human error, businesses can save money on inventory costs. This also includes avoiding the cost of overstocking or running out of essential items.

Must-have Features in an Automated Inventory Management System

Every business has different inventory management needs, and the ideal automated system should cater to those specific needs. However, some key features that you must look out for when choosing an inventory management system include:

- Real-time tracking: The system should provide a real-time view of your inventory levels, orders, and sales.

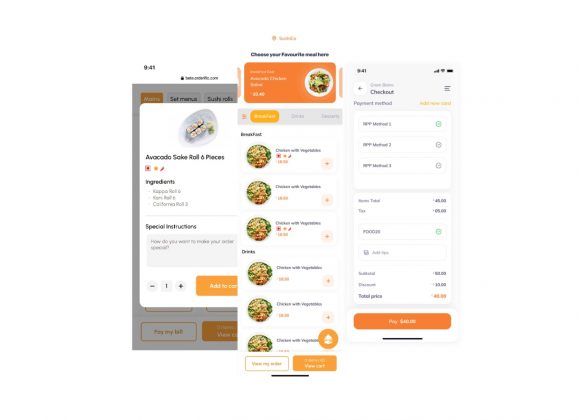

- Integrations: The ability to integrate with other systems, such as accounting software and e-commerce platforms, can make inventory management more seamless.

- Scalability: As your business grows, so will your inventory. Therefore, it’s crucial to choose a system that can accommodate your future needs.

- Customization: The system should allow for customization to fit your unique business requirements.

How to Successfully Implement an Inventory Management System in 2023?

Ready to take the leap and streamline your business operations with an automated inventory management system? Excellent decision! But, like any new business tool, the key to reaping its full benefits lies in successful implementation.

“What” Stage: Do the Research and Define What Your Requirements Are

The first step towards implementing an automated inventory management system begins with understanding your business needs. Research and analysis are crucial at this stage. Start by looking at your current inventory system and identifying areas where automation could bring about an improvement. Are you struggling with inaccurate inventory counts, inefficient order processing, or overstock issues? Once you’ve pinpointed the challenges, determine the specific features you need in your automated system to address these issues. This may include real-time tracking, barcode scanning, integration with your existing systems, etc. Remember, your goal is to find a system that fits seamlessly into your operations and enhances your supply chain management. Hence, define your requirements clearly and specifically.

“Who” Stage: Choose the Technology Vendor that Will Implement the System

After defining your requirements, the next step is to choose the right technology vendor to implement the system. This involves thorough research and comparison of various vendors based on factors like their reputation, expertise, customer reviews, and post-implementation support. Don’t rush this step; take your time to engage with different vendors, ask for demos, and ensure they can cater to your specific needs. Remember, the right vendor is not just a service provider, but a partner who will contribute to the success of your inventory management system implementation.

“When” Stage: Determine the Timeline and Budget for the Project

Once you have selected the technology vendor, it’s time to set a timeline and budget for the project. This is a critical stage that requires careful planning and coordination with your chosen vendor. Based on your business needs, decide on the implementation timeline, keeping in mind any potential disruptions to your regular operations. Set a realistic budget that covers all aspects of the project, including software costs, hardware costs, training, and post-implementation support. Remember, investing in a quality system will pay off significantly in the long run.

Conclusion

Implementing an automated inventory management system is a significant step towards streamlining your business operations and optimizing your supply chain. It’s a strategic investment that yields substantial returns in terms of efficiency, accuracy, cost savings, and overall business growth. It provides you with real-time insights, automates tedious tasks, reduces errors, and empowers you to make data-driven decisions.

While the implementation process may seem daunting at first, with careful planning, research, and the right technology partner, it becomes manageable and rewarding. Remember, the key to successful implementation is understanding your specific needs, choosing a system that caters to these needs, and working with a reliable technology vendor.

You can find more informative content with Orderific here. For the countless benefits Orderific can bring to your business, start trying it out here. Today is Orderific time!

FAQs

What is an automated inventory management system?

An automated inventory management system is a technology-based tool that automates the process of tracking goods and materials as they move through the supply chain.

How does an automated system differ from manual inventory management?

An automated system eliminates the need for manual record-keeping and data entry, reducing the risk of human error.

What are the benefits of using an automated inventory management system?

The main benefits are real-time tracking, reduced human error, improved efficiency, and cost savings.

Can the system handle real-time updates and tracking?

Yes, a good automated system offers real-time tracking of inventory levels, orders, sales, and deliveries.

Is the system compatible with various types of businesses and industries?

Yes, most automated inventory management systems can be tailored to fit the specific needs of different businesses and industries.