In today’s fast-paced retail environment, having an efficient Automated Inventory Tracking system isn’t just an option, it’s a necessity. The old-school methods of tracking stock manually – jotting down figures, scanning barcodes, tallying numbers – are no longer feasible. They are time-consuming, prone to human error, and can lead to inefficiencies in the supply chain.

Enter Automated Inventory Tracking – the game-changer your business needs. This technology ensures that you always have real-time insights into your inventory levels, making overstocking and stockouts a thing of the past. By automating your inventory management, you’re not just streamlining your operations; you’re setting your business up for success in an increasingly competitive market. So, let’s take a closer look at why automated inventory tracking is the magic wand in effective supply chain management.

Tips for Managing Your Inventory

Before we dive into the transformative power of Automated Inventory Tracking, let’s refresh some tried-and-true inventory management tips. These foundational strategies will not only help you maintain control over your stock levels but also pave the way for a seamless transition to an automated system. Pair these tips with cutting-edge inventory tracking technology to truly supercharge your supply chain management.

Prioritize Your Inventory for Better Inventory Management

Not all products are created equal, and neither should your inventory management strategy be. Assess which items are selling the most and prioritize them over slow-moving or seasonal products. This will help you focus on managing your top-selling items while freeing up time for other important tasks.

Track All Product Information to Manage Inventory Better

Tracking data such as product SKUs, descriptions, and prices can make a world of difference when it comes to inventory management. A comprehensive record of this information will not only help you keep track of your products but also aid in forecasting demand, ensuring that you always have the right amount of stock on hand.

Audit Your Inventory for Better Inventory Management

Manual data entry can be a time-consuming and error-prone process. By automating these tasks, you not only save valuable time but also reduce the risk of human error in your inventory management. This will lead to more accurate stock levels and better decision-making.

Analyze Supplier Performance for Better Inventory Management

Analyzing supplier performance is a crucial aspect of effective inventory management. Regular assessments of your suppliers can give insights into their reliability, delivery speed, product quality, and overall performance. Automated inventory tracking systems make this process more efficient by providing real-time data about your suppliers. By identifying suppliers who consistently deliver on time, offer high-quality products, and respond quickly to any issues, you can ensure a smooth, reliable supply chain. This proactive approach can help you avoid stockouts, delays, or product quality issues that can harm your business reputation and bottom line.

Practice the 80/20 Inventory Rule for Better Inventory Management.

The 80/20 inventory rule, also known as the Pareto principle, states that roughly 80% of sales come from just 20% of your products. This means that a majority of your profits are generated by a small number of high-selling items. By focusing on these top-performing products and keeping them well-stocked, you can maximize profits and minimize the risk of stockouts.

Be Consistent in How You Receive Stock for Better Inventory Management

Having a standardized process for receiving and tracking stock is crucial in maintaining an efficient inventory management system. This not only helps to avoid errors but also ensures that all stock is accounted for and easily traceable.

Track Sales for Effective Inventory Management

Regularly tracking sales is vital for understanding customer demand and making informed decisions about replenishing stock levels. Automated inventory tracking systems provide real-time updates on sales, giving you the data you need to make accurate forecasts and optimize your stock levels.

Order Restocks Yourself for Better Inventory Management

Taking control of the restocking process is another important aspect of effective inventory management. While it’s tempting to delegate this task or rely solely on automated systems, having a personal touch in the ordering process can provide deeper insights into your inventory needs. By manually ordering restocks you have an opportunity to review your sales trends, assess the performance of different products, and get firsthand knowledge of your inventory levels. This hands-on approach allows you to make more informed decisions about what, when, and how much to restock, potentially saving your business from overstocking or understocking issues. Nevertheless, the aim is to complement, not replace, the automated system. The insights you gain from this process can be imperative in fine-tuning your automated inventory tracking system for even better results.

Invest in Inventory Management Technology

A successful inventory management strategy requires efficient processes and accurate data. That’s where automated inventory tracking technology comes in. With real-time updates on stock levels, sales trends, and supplier performance, this technology takes the guesswork out of inventory management. Not only does it save time and reduce errors, but it also provides valuable insights for informed decision-making.

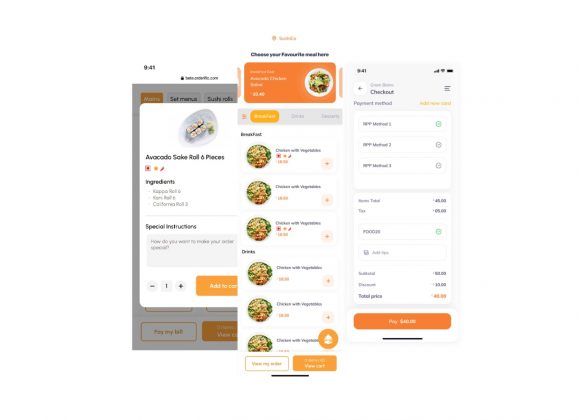

Use Inventory Management Tools that Integrate with Your Other Solutions

Efficient inventory management requires seamless communication and coordination between different systems. That’s why it’s important to invest in inventory management tools that can integrate with your existing solutions, such as POS systems and accounting software. This integration streamlines processes, reduces data entry errors, and allows for more accurate forecasting.

Conclusion

Efficient inventory management is the backbone of a successful retail business. By prioritizing your inventory, tracking data, auditing stock levels, analyzing supplier performance, and utilizing automated technology, you can streamline your supply chain and maximize profits. Make use of these tips to lay the groundwork for a smooth transition to an automated inventory tracking system that will revolutionize the way you manage your stock.

With real-time insights and more efficient processes, you’ll have the magic touch in inventory management. So wave goodbye to manual tracking methods and hello to automated inventory tracking – your ticket to streamlined stock management and business success.

Click here for more informative advice with Orderific. To start experiencing the great benefits Orderific can bring to your business, click here now. Try Orderific!

FAQs

What is automated inventory tracking and how does it work?

Automated inventory tracking is a system that uses technology, such as scanners and barcodes, to automatically keep track of stock levels in real time.

What are the benefits of implementing automated inventory tracking in my business?

Implementing automated inventory tracking can save time, reduce errors, provide valuable insights for decision-making, and streamline your supply chain management.

Can automated inventory tracking help prevent overstocking and stockouts?

Yes, automated inventory tracking provides real-time data on stock levels, allowing businesses to make more accurate forecasts and avoid overstocking or stockouts.

Is automated inventory tracking compatible with different types of businesses and industries?

Yes, automated inventory tracking can be customized to fit the needs of various types of businesses and industries.

What features should I look for in an automated inventory tracking system for my business needs?

You should look for features such as real-time updates, integration with other solutions, customizable options, and user-friendly interfaces.